As the chemical industry imposes increasingly stringent requirements on the safety and efficiency of liquid packaging, Zhenjiang Chuangda Packaging Co., Ltd. has provided high-quality solutions for the industry with its independently developed core technologies. It is reported that the company has successfully developed a 1000L intermediate bulk container (IBC) frame assembly line equipment and is equipped with a 1000L large-scale double-layer blow molding machine, realizing mechanized and automated control of the entire production process of chemical packaging products, which effectively improves product consistency and production efficiency.

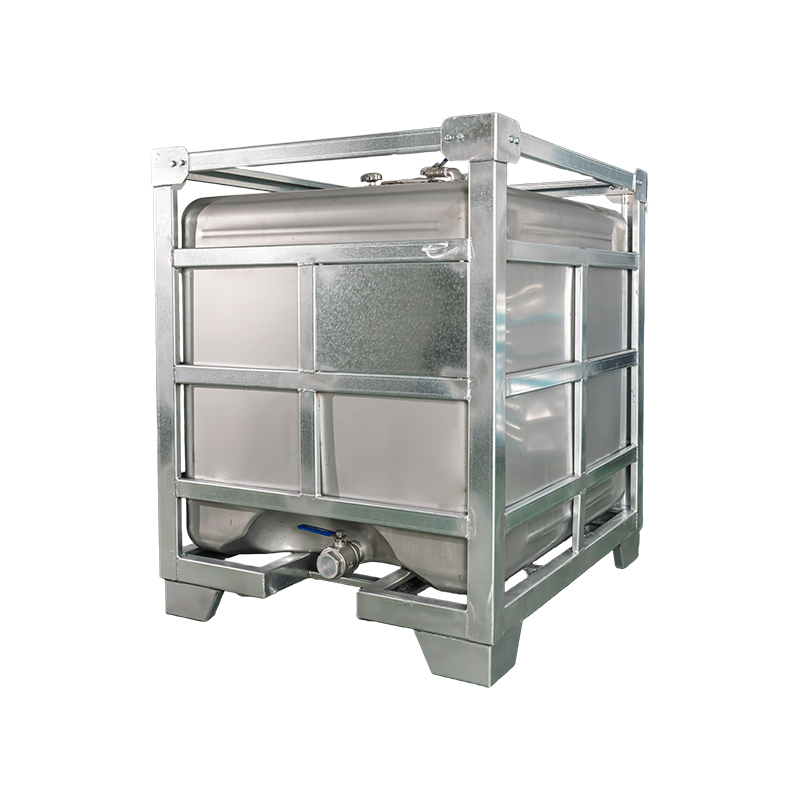

As a professional enterprise focusing on the chemical packaging field, Chuangda Packaging mainly engages in a full range of products such as stainless steel ton drums, new IBC ton drums, and plastic packaging drums, with an annual output of 100,000 units. Relying on independently developed production equipment, the company has not only broken the limitations of traditional production models but also established a strict quality control system — products not only follow high internal corporate standards but also undergo full-process testing in strict accordance with the national standard GB/T19161-2016, ensuring that each product has excellent safety performance.

"Our core goal is to provide maximum safety guarantees for the transportation of liquid products," said a relevant person in charge of the enterprise. The combination of automated production processes and strict quality inspection procedures enables Chuangda's core products, such as IBC ton drums, to perfectly meet the special needs of the chemical industry, making it a trusted packaging partner for many chemical enterprises. In the future, the company will continue to deepen technological innovation and build a stronger safety packaging barrier for the industry with better products.

English

English